Each day countless engines get prepared for transport all over the country. The majority of these engines are shipped from engine reconditioning and rebuilding shops as well as wreckers. Due in part to advances in communication technology, an increasing number of engines are transported on a private scale as well, all over Australia.

The physical process of preparing an engine for transport involves several critical steps, listed below in the logical order:

- Drain all oil and fluids from the engine

- Place the engine inside a strong, forklift friendly wooden crate

- Strap the engine securely down to the bottom of the crate

- Book your transport with a reputable freight company

- Securely attach any address labels

We’ll cover these steps in more detail further down, but first, let’s explore some of the main drivers behind the engine transportation industry.

Car Enthusiasts and Spare Parts Bargain Hunters

The rise of social media has seen an unprecedented increase in the sharing of both knowledge and materials between car enthusiasts, through to pretty much anyone looking for second hand parts. Whereas a decade or two ago, if you were looking to sell or trade an engine you would need to rely on your local paper, the internet has created a far broader reach all over Australia and beyond, and subsequently a much greater buyers and sellers market.

If the engine you are sending off is beyond repair and is simply being transported to a scrap metal yard or similar, your only real concern is to ensure it doesn’t become dislodged during transport. Given the fact that an average engine weighs well over 100 kilograms, it has the potential to become a lethal missile if left unsecured in the unfortunate event of an accident.

“If an engine is beyond repair and is simply being transported to a scrap metal yard, your main concern is to prevent it from becoming dislodged.”

Other reasons an engine may require transporting are if it is being sent to a specialist repairer. Procedures such as reconditioning of cylinder heads, engine block machining, through to performance modifications being carried out on it to improve power output – any of which might be beyond the scope of your standard automotive service centre or backyard mechanic.

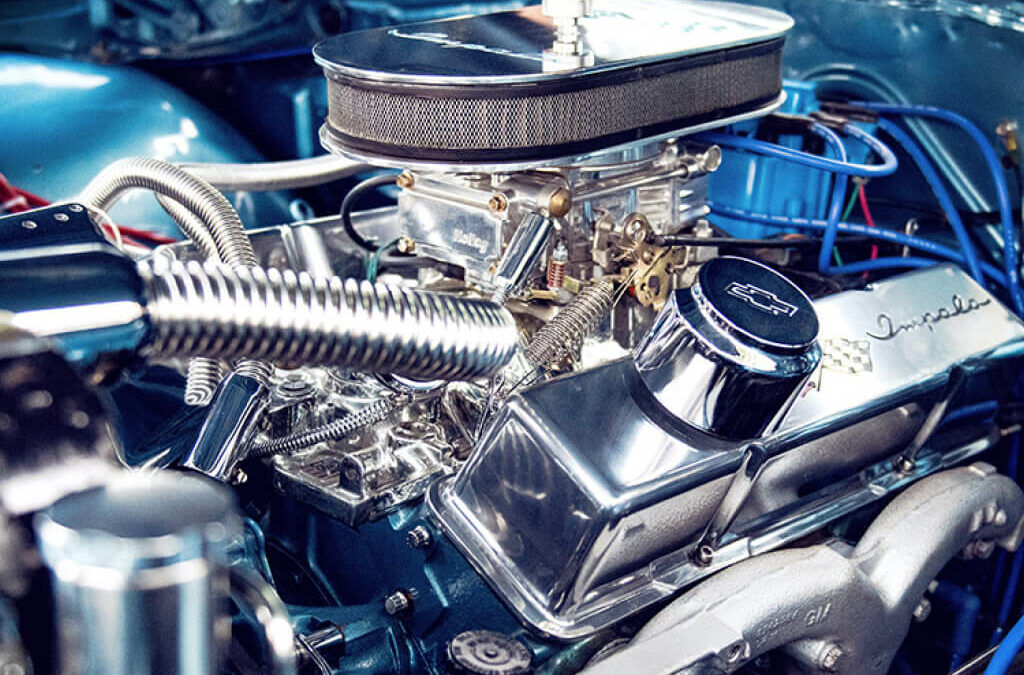

Although a car’s performance can be significantly improved through modifications to the intake, exhaust and tuning of the ecu, every engine reaches the point where if more power is to be achieved, the car will need to be taken to a workshop specialising in performance engines. If engine work is only one aspect of modifications being carried out on the vehicle, the engine will be removed and freighted to an engine performance workshop for the internals to be strengthened, or replaced with performance parts capable of dealing with a higher power output.

Enhancing your Engine? Don’t Forget the Rest of the Drive-train!

When enhancing the performance of an engine, it’s easy to forget that the rest of the drivetrain, from the transmission right through to the tyres and brakes, may potentially need to be modified to cope with the enhanced power plant under the bonnet. There is little point in increasing the performance of an engine without budgeting in sports suspension, better tyres and larger brakes to cope with the extra demands which will be placed on them. This aspect of modifying a car is relevant to all aspects of it, not just the engine. Working back from the engine, the next step might involve installing a heavy duty clutch capable of transferring the increased power from the engine to the gearbox. With the heavier duty clutch installed, the gearbox is put under a great deal more strain, which when coupled with wider, grippier tyres, significantly increases the stress placed on the differential… and so on.

Financially it may be more economical to purchase a car which already carries many of the sportier design elements required to cope with horsepower gained from an engine rebuild. Once an engine has been rebuilt, the overall cost of the project rarely adds significantly to the resale value of the car. Depending on consumer demand for a particular make and model car, a significant portion of the costs invested in modifying a car will never be recouped upon sale of the vehicle. This is why 4×4 enthusiasts in particular, will sometimes transfer any modifications over to their new vehicle when upgrading, or sell them individually.

“As a rule, a significant portion of the costs invested in modifying your car will never be recouped if you decide to sell your vehicle.”

This also applies to performance engines. A car enthusiast who has the time to wait for the right buy, may be able to get a far more affordable performance car through the purchase of another person’s completed project, rather than starting from scratch and having to wear every individual cost of it. In saying that, those who have done it know that there is a certain satisfaction gained from modifying an engine yourself and knowing the complete history of the car, as opposed to doing it the easy way and purchasing someone else’s hard work.

Specialist Mechanical Workshops

In the past, more automotive mechanical workshops would be a one-stop-shop for every automotive repair, including engine rebuilding. With the influx of businesses specialising in engine rebuilds and change over engines, many mechanical workshops find it more cost effective to make use of the different workshops that specialise in one particular component of the drive train. In a large industrial estate you will often find a number of these in close proximity to each other, each focusing on their own niche.

Limited Incentives for Local Garage Mechanics

Although making use of all these niche service centres can be convenient for a local automotive garage, it also means a certain percentage of potential profits are lost through outsourcing the above-mentioned work – regardless of whether or not they’re able to charge a bit extra for doing the running around for their customer.

Take for example a faulty power steering system. A customer drops their car off at the local mechanic. The mechanic diagnoses the problem as a faulty power steering rack and calls up the power steering mob around the corner for a price on a change over power steering rack. He then adds a labour charge for removal and refitting and provides the customer with a quote for the job. If the mechanic in question had the experience to be able to remove the power steering rack and disassemble it on the workbench himself, he may have found that all it needed was a couple of replacement seals to rectify the fault. This would have kept the whole job ‘in house’ and significantly increased his profits on the job. In all likelihood, he would still be justified in charging the market rate for the job without replacing unnecessary components.

One reason why many mechanical workshops don’t operate this way anymore is that car components are typically becoming throw away items. It is often far cheaper and faster to purchase an exchange motor or transmission than waiting for one to be rebuilt. This in turn, creates a far more positive experience for the customer who spends less time waiting for their car to be repaired and more time driving it.

Preparing An Engine Block for Transport

One of the essentials when preparing an engine for transport is ensuring all fluids are drained. This includes engine oil, as well any coolant that may still be in the engine block. Aside from the obvious prevention of mess incurred through spills, it also removes the hazards associated with slippery surfaces and minimises the possibility of causing damage to the environment during the engine freight process. Always use gloves around oils and coolants, as frequent and prolonged skin contact with used engine oils, has been known to cause dermatitis and other skin problems.

The next step would be to build an engine transport crate. Find a suitably sized pallet and build a frame using pieces of timber screwed down to the pallet itself to ensure the engine sits snugly and is not going to move. Essentially what you want is a crate on pallet skids, as most transport companies will not accept an open pallet. An alternative to knocking together a custom frame would be to purchase an engine cradle specific to the engine you are transporting. This is a sturdy frame which can be physically bolted to the engine and then secured onto a pallet.

Use ratchet straps or other adjustable type, heavy-duty straps, and fix these length ways and sideways to ensure that both frame and engine remain firmly secured to the pallet. Consider wrapping the entire load in plastic to ensure there is no chance of dust or water getting in and contaminating the engine.

Manual Handling and other Safety Precautions

As a rule you should never attempt to physically drag or manoeuvre an engine onto a pallet on your own; engines are heavy (often upwards of 150kg) awkwardly shaped and you risk injuring yourself and any close bystanders. All engines have lift points for the purpose of securing a chain or sling when removing the engine from a vehicle, and these can also be used when placing the engine onto the pallet. A simple engine crane like this one from Supercheap Auto is highly recommended, unless you’re garage is already equipped with a more advanced hoist system.

The above steps cover the transport preparation of a short or long block engine. ‘Short’ being basically the engine block by itself, with associated components including the crankshaft, pistons and connecting rods. A ‘long block’ engine has all those elements as well as cylinder heads, valve train and camshaft, oil pump, water pump and the engine sump plus a few other parts.

Preparing a Complete Engine for Transport

Let’s assume you’re selling an engine. Unless you already have locked in a buyer, consider making a video clip of the engine running, prior to removing it from the vehicle as this could put potential buyers at ease, making the sale process easier. Keep any documentation that displays evidence of how many kilometres are on the engine. This might be something as straightforward as the most recent registration papers containing the engine number coupled with a photo of the dash cluster ensuring the odometer reading is clearly visible.

Once the engine is removed from the vehicle, there are various components that are particularly prone to damage. These include items that may be broken or crushed due to their exposed location, such as wiring looms, oil and temperature sensors. If in doubt, err on the side of caution and remove and package these kinds of items separately to ensure they reach their destination in their original condition.

Regardless of whether you plan to take out freight insurance, it is always a good idea to take photos of the engine and various components prior to shipping as evidence of the condition it was in. It is hard to dispute time-stamped photographic evidence. Note that, without freight insurance, you have very little hope of recovering any costs relating to damage which might occur during transit.

Once, your engine is crated and ready for transport, you’ll need to get some engine transport quotes. In order to provide you with a quote, the transport company or freight broker will need to know:

- Pick up an delivery locations

- The dimensions

- The weight

- Whether a tail-lift or crane is required at either end.

Fix Labels Firmly To the Engine Transport Crate

Once you’ve locked in the freight, transport companies will usually email you some labels which you’ll need to print out and attach to the consignment. Take great care when fixing these to the crate, and ideally tape over them with some robust transparent packaging tape, minimising the chances of the labels becoming dislodged due to wind, rain or other factors.

This information is general in nature and we accept no responsibility for consequences arising from the use or reliance on this article. If you need assistance transporting an engine, please feel free to submit a Quote Request.